Event Overview

Big data. Analytics. Internet of Things. Advanced robotics. AI. Augmented and virtual reality. It's the world as we know it thanks to Industry 4.0. Traditional manufacturing meets the ever-evolving world of digital transformation.

Are you on top of your I4.0 game?

Industry 4.0 is revolutionizing the manufacturing industry. Download our guide to your digital future at the Industry 4.0 Workshop for Manufacturers as we explore the adoption of new technologies and cyber-physical systems, disruptive trends in data acquisition, implications to the industrial workforce, and the integration of collaborative robots and assistive devices to automate tasks and support employee safety in modern manufacturing environments.

Join Us June 22!

Agenda

| **Agenda subject to change** |

| THURSDAY, JUNE 22 |

| 9:00 a.m. Registration & Networking |

| 9:45 a.m. Welcome & Introductions Dr. Greg Harris - Director, Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS), Auburn University Ron Davis - President, Alabama Automotive Manufacturers Association |

| 10:00 a.m. Industry 4.0 Overview, Workforce & the State of Technology Adoption Dr. Greg Harris - Director, Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS), Auburn University >> What does Industry 4.0 mean to manufacturers in the automotive industry, and what is the current state of technology adoption, particularly by small- and medium-sized manufacturers? What is different with the Gen Z workforce? What does this mean for the industrial workforce, and what will jobs look like in 2030? |

| 11:00 a.m. Modern Machine Data Flow Using the MTConnect Standard Methods Samuel Snell - Research Engineer, Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS), Auburn University Scott Neff - Research Engineer, Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS), Auburn University Dr. Lewis Payton - Professor of Practice & Associate Director of Operations, Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS), Auburn University >> Major machinery brands are all offering options that say they are "MTConnect" compatible for acquiring data with different degrees of compliance. What should you look for when purchasing this option? How do you utilize these tools to evaluate Overall Equipment Effectiveness (OEE)? These topics and the "flow of information" will be discussed. **Interactive audience discussion period will follow the presentation.** |

| 12:00 p.m. - Working Lunch Break Live Demo Presented by Air Hydro Power >> Featuring >> AHP Industry 4.0 Tools |

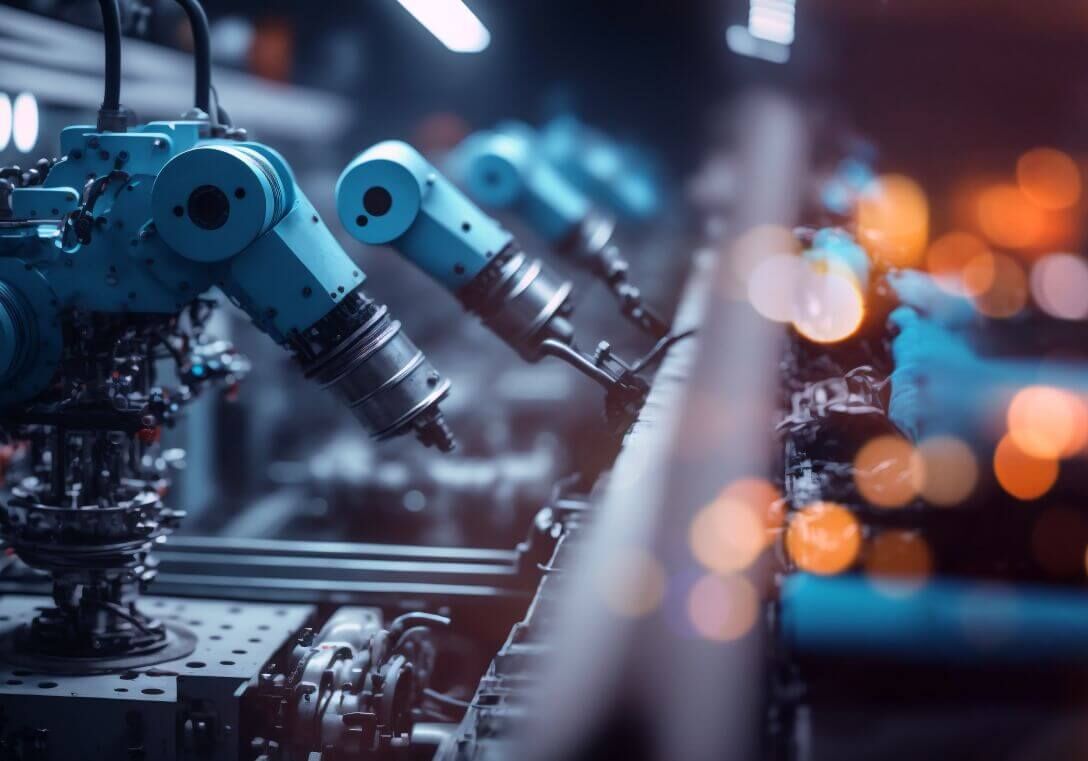

| 12:30 p.m. - Traditional and Collaborative Industrial Robots: Levels of Implementation & Safety Aspects Michail Katsigiannis - PhD Researcher, Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS), Auburn University Minas Pantelidakis - PhD Researcher, Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS), Auburn University, Auburn University Dr. Konstantinos Mykoniatis - Assistant Professor, Industrial Systems & Engineering Department, Auburn University >> A robot can perform dirty, unsafe, boring, monotonous or repetitive tasks so that employees can concentrate on other tasks. How do you choose between collaborative and traditional industrial robots? What are the different methods to program a robot, and what resources are available for training? Different ways to program a robot and how to get a free certification with collaborative robots will be presented. **Interactive audience discussion period will follow the presentation.** |

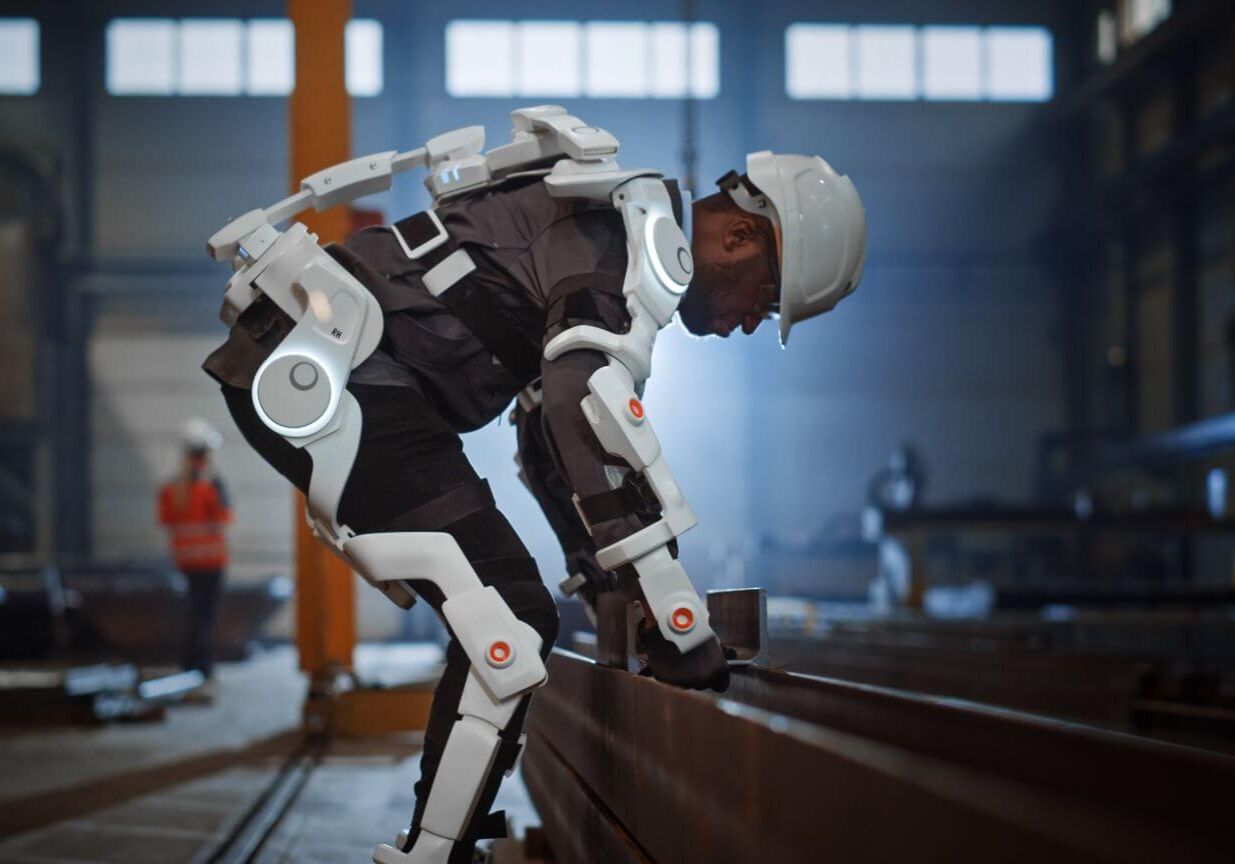

| 1:30 p.m. - Exoskeletons to Support Industry 4.0 Workers Dr. Mark Schall - Associate Professor, Industrial Systems & Engineering Department, Auburn University Dr. Yadrianna Acosta-Sojo - Assistant Professor, Industrial Systems & Engineering Department, Auburn University >> Exoskeletons are assistive devices that can be worn to increase strength and endurance. Which exoskeletons may be best suited for small- and medium-sized manufacturing environments? Which tasks can be completed while wearing an exoskeleton? We will provide a brief introduction to exoskeletons. Following the presentation, attendees can gain hands-on experience exploring several low back and upper limb exoskeletons to assist with lifting and overhead work tasks. **Interactive audience discussion period will also follow the presentation.** |

| 2:30 p.m. - Live Demo Presented by Air Hydro Power >> Featuring >> AHP Industry 4.0 Tools |

| 2:30 p.m. - ICAMS Tour >> Optional |

Ready to Start Smart Manufacturing?

Attend

Network & Connect!

Attendee Registration

AAMA Members - $25

Non-members: $50

Sponsor

Make an Impact!

Sponsorships At-a-Glance

Presenting Sponsor

$500

Includes speaker introduction, opportunity to address audience with brief presentation, logo on event marketing/program/signage, 4 complimentary registrations.

Platinum Sponsor

$250

Includes logo on event marketing/program/signage, 2 complimentary registrations.

**To secure your sponsorship,

please complete the form at the link below!**

Venue

Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS) at Auburn University

1490 Pumphrey Avenue

Auburn, Alabama 36830

(in the Auburn Industrial Park)

About ICAMS

The Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS) at Auburn University is an important resource for small and medium manufacturers throughout the southeastern United States. Established in 2018, ICAMS offers the equipment, space and expertise to train and educate students and industry personnel in advanced manufacturing technologies. ICAMS’ efforts focus on reducing the barriers inhibiting the introduction of advanced manufacturing systems (e.g, the implementation of Industry 4.0 technologies) in small and medium manufacturing operations.

Questions?

For more information, please contact:

Madison Bosc - General Event Inquiries

madisonaama@gmail.com

Lynsey Delane - Registration Questions

lynsey.aama@gmail.com

Thank You To Our Sponsors!